The John Deere Range

Power you can rely on, reliability you can count on.

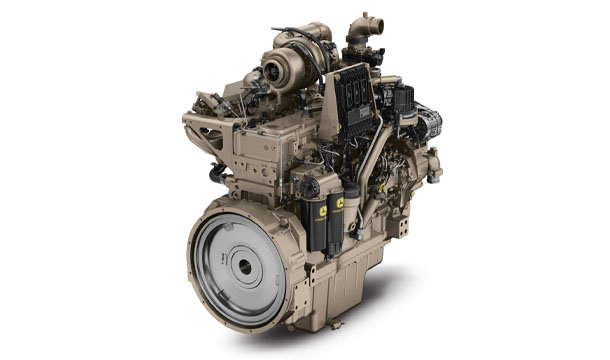

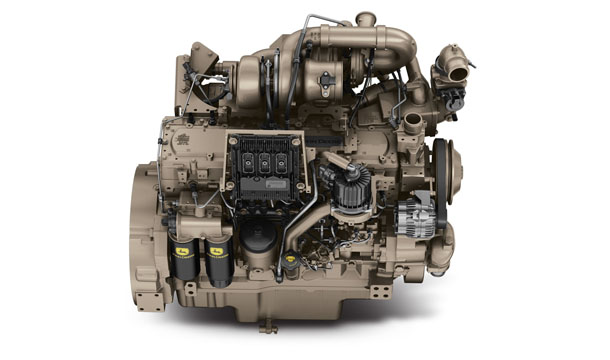

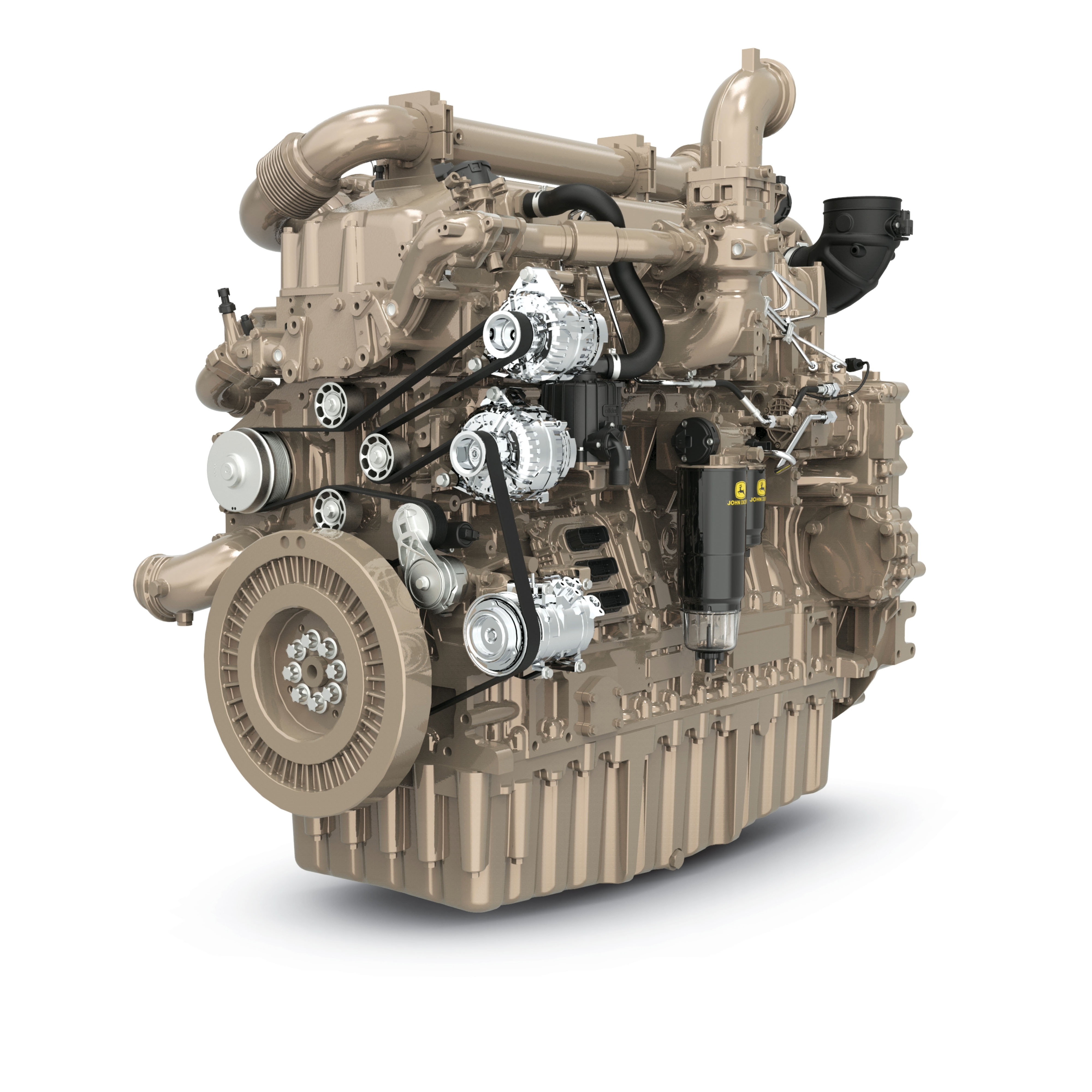

John Deere PowerTechTM Diesel Engines

John Deere PowerTechTM Diesel Engines are renowned for their long-lasting durability, reliability in tough conditions, and ability to complete critical jobs on schedule. Performance, fuel efficiency, dependability, and ease of installation and operation are the keywords that characterise John Deere engines.

John Deere’s continuing research and development efforts are fundamental to the constant improvement of its engines. The commitment to technology excellence and a rigorous manufacturing process are the best guarantees of each engine’s precision.

Their proven off-highway experience means that the PowerTechTM engine family has different technologies to tackle a wide range of applications.

Generator Drives - Stationary & Export Applications

PowerTech M Output: 28 kW(38 hp) - 61 kW(82 hp)

PowerTech E Output: 75 kW(101 hp) - 287 kW(384 hp)

EASY MAINTENANCE John Deere design their engines to facilitate maintenance. The interchangeable wet sleeves enable better temperature control in the combustion chamber and optimise engine performance. They can be replaced on site without having to remove the engine, thus minimising the machine's downtime and maintenance costs. By using helical-cut gears, engine noise is reduced along with maintenance costs. The crankshaft bearings, camshafts and cylinder heads are also interchangeable.

RELIABILITY John Deere's sturdy, compact engine blocks are the basis of our products' longevity. But John Deere is also the guarantee of numerous technological assets, which themselves are synonymous with reliability. For example, the dynamically balanced moving parts, such as the track rod and crankshaft, make the engine quieter and limit vibrations, while the automatic belt tightener minimises maintenance costs and increases belt life. In addition, several functions, such as the thermostat box and the intake air collector, have been built into the cylinder head to limit the risk of leakage.

EASY INSTALLATION The engine is installed into the machine by using the engine block's front and side mounts. John Deere offer several options and variants in order to ensure their engines' perfect integration and guarantee easy access to the service points for the entire service life of the engine.

QUALITY John Deere's continuing research and development efforts are the key to the constant improvement of their engines. The commitment to technology excellence and a rigorous manufacturing process are the best guarantees of each John Deere engine's precision. Performance, fuel efficiency, reliability and easy installation, in keeping with environmental standards, are the key words that characterise their engines.

Generator Drives - Stage V & EPA Final Tier 4 Applications

CONFIDENCE IS BUILT IN You can count on John Deere PowerTech™ generator drive engines to start in the morning, operate efficiently all day, and work reliably for many years. You also get the confidence of having the John Deere integration and support network at your side every step of the way.

PRIME OR STANDBY POWER John Deere generator drive engines are ready when and where you need them. They provide fast response for standby situations and exceptional load recovery in a wide variety of applications.

THE POWER OF CHOICE Why build your gen-set around someone else’s engine? With John Deere, you get a wide range of configurations and accessories so you can specify the right generator drive engine that best fits your application. Our preconfigured options can save you hours of engineering time and help you get machines to market faster.

INTEGRATION ASSISTANCE You get expert integration assistance provided by John Deere engineers and distributors. OEMs can put our application engineering experience and know-how to work to save development time and money.

Variable Speed - Export Applications

PowerTech M Output: 56 kW(75 hp) - 74 kW(99 hp)

PowerTech E Output: 63 kW(85 hp) - 149 kW(200 hp)

PowerTech Plus Output: 111 kW(149 hp) - 448 kW(600 hp)

POWERTECH M - 2.9L & 4.5L Engines

The simplest of the PowerTech family, these engines have 2-valve heads, fixed geometry turbochargers and mechanical fuel systems. PowerTech M engines (4.5L) are perfect for less demanding applications. their mechanical controls are simple to operate and maintain.

FIXED GEOMETRY TURBOCHARGER Fixed geometry turbochargers are sized for a specific power range and optimized to provide excellent performance across the entire torque curve. They are also designed to maximize fuel economy between the engine's rated speed and peak torque.

MECHANICAL UNIT PUMP (MUP) FUEL SYSTEM This system uses camshaft-driven MUPs, connected to the injectors by a short fuel line. The short fuel line between the unit pumps and the injectors helps to alleviate after-injection, secondary injection, and other injection abnormalities (2.9L).

MECHANICAL ROTARY PUMP The timing and fuel injection pressures are optimised to maximise performance and fuel economy at a given rated speed (4.5L).

2-VALVE CYLINDER HEAD Cross-flow (4.5L) and U-flow (2.9L) head design provides excellent breathing from a lower-cost 2-valve cylinder head.

TURBOCHARGED In turbocharged engines, the air is pre-compressed. Due to the higher pressure, more air is supplied into the combustion chamber, allowing a corresponding increase in fuel injection, which results in greater engine output.

COMPACT SIZE Mounting points are the same as previous engine models.

ADDITIONAL FEATURES - Self adjusting poly-vee fan drive - Forges steel connecting rods - Either-side service - 500 hour oil change - Glow plugs(2.9L)

- Optional balancer shafts

POWERTECH E - 4.5L, 6.8L & 9.0L Engines

These engines also have 2-valve heads and fixed geometry turbochargers, but introduce full-authority electronic controls and more sophisticated fuel delivery- high-pressure common-rail (HPCR) fuel systems.

FIXED GEOMETRY TURBOCHARGER Fixed geometry turbochargers are sized for a specific power range and optimized to provide excellent performance across the entire torque curve. The are also designed to maximize fuel economy between the engine’s rated speed and peak torque.

HIGH-PRESSURE COMMON-RAIL (HPCR) AND ENGINE CONTROL UNIT (ECU) The HPCR fuel system provides variable common rail pressure, multiple injections, and higher injection pressures, up to 1,600 bar (23,000 psi). It also controls fuel injection timing and provides precise control for the start, duration, and end of injection.

2-VALVE CYLINDER HEAD Cross-flow head design provides excellent breathing from a lower-cost 2-valve cylinder head.

4-VALVE CYLINDER HEAD The 4-valve cylinder head provides excellent airflow (9.0L).

TURBOCHARGED In turbocharged engines, the air is pre-compressed. Due to the higher pressure, more air is supplied into the combustion chamber, allowing a corresponding increase in fuel injection, which results in greater engine output (4.5L).

AIR-TO-AIR AFTERCOOLED This is the most efficient method of cooling intake air to help reduce engine emissions. It enables an engine to meet emissions regulations with better fuel economy and the lowest installed costs.

COMPACT SIZE Mounting points are the same as previous engine models.

JOHN DEERE ELECTRONIC ENGINE CONTROLS Electronic engine controls monitor critical engine functions, providing warning and/or shutdown to prevent costly engine repairs and eliminate the need for add-on governing components, all lowering total installed costs.

ADDITIONAL FEATURES - Self-adjusting poly-vee fan drive - Forged-steel connecting rods - Replaceable wet-type cylinder liners - Either-side service - 500-hour oil change - Gear driven auxiliary drive - Optional balancer shafts(4.5L)

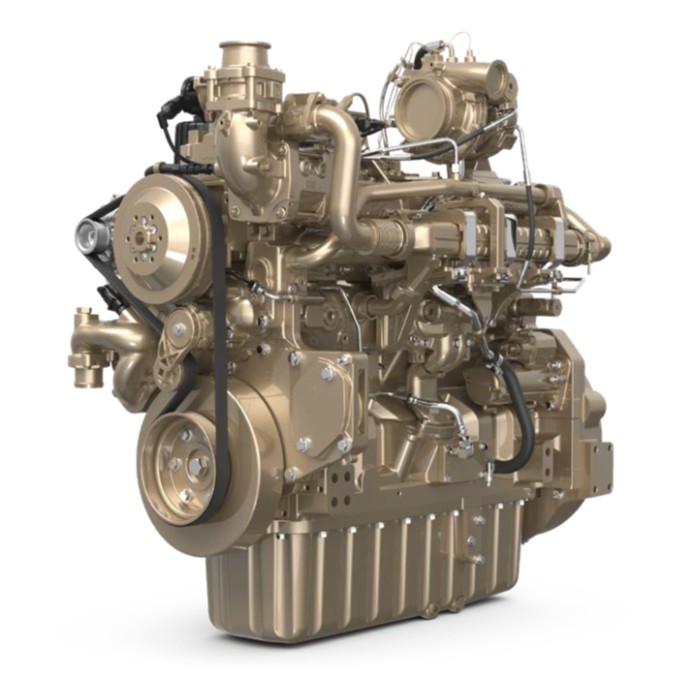

Variable Speed - Stage V & Final Tier 4 Applications

THE RIGHT TECHNOLOGY FOR MAXIMUM PERFORMANCE John Deere PowerTech Final Tier 4/Stage IV engines, 56kW (75hp) and above, are built on a proven platform of emissions control technologies including cooled exhaust gas recirculation (EGR), exhaust filters, and selective catalytic reduction (SCR). You can count on John Deere engines to deliver reliable power day in and day out, year after year, and in the toughest off-highway working conditions. John Deere Final Tier 4/Stage IV engines maintain power density, torque and transient response. It all adds up to more productivity, uptime, and value for your machines.

POWERTECH EWX EWX engines are compact, powerful, cost-effective and simple to install without requiring cooled EGR or SCR. Our straightforward PowerTech™ EWX engines have 2-valve cylinder heads, high-pressure common rail fuel systems and full authority electronic controls. They use simple wastegate turbocharging to maintain transient response and peak torque in all operating conditions.

POWERTECH EWS EWS engine meet performance and emission requirements without requiring cooled EGR. PowerTech EWS engine have 2-valve cylinder heads, high-pressure common-rail fuel systems and full authority electronic controls. They use simple wastegate turbocharging to maintain transient response and peak torque in all operating conditions.

POWERTECH PWS PWS engines combine advanced combustion technologies, enhanced engine calibration and simple wastegate turbocharging. PWS engines feature PowerTech Plus technology with a DOC/DPF and an SCR system that reduce emissions while maximising performance.

POWERTECH PVS PVS engines deliver more power, torque and fluid economy. They utilise our proven PowerTech Plus technology with variable geometry turbocharging, a DOC/DPF and an SCR system to improve combustion efficiency, reduce emissions, enhance performance and improve fuel efficiency.

POWERTECH PSS PSS engines provide a powerful combination of power density, performance and fluid efficiency. For ultimate performance in off-highway applications. PowerTech PSS engines can handle almost any job. All displacements feature series turbochargers to deliver excellent performance and responsiveness. PSS engines feature proven PowerTech Plus technology that includes a DOC/DPF and an SCR system designed specifically for off-highway applications.

Up and Coming JD4 Engine JD4 Output : 63 kW (84 hp) - 120 kW (161 hp)

ENGINE PERFORMANCE New to the John Deere engine lineup, the JD4 provides up to 120 kW (161 hp) of power. It features a rear gear train that offers customers low noise and higher PTO power. The engine also has an extended single turbo range and provides 700 Nm (516 lb-ft) of maximum torque for improved high-load capacity and productivity.

RELIABILITY AND UPTIME The JD4 offers a more reliable diesel exhaust fluid (DEF) delivery system. The engine also features extended fluid service intervals of 750 hours (1,000 hours possible), reducing maintenance costs for customers. Hydraulic lash adjusters decrease valve wear and eliminate valve lash maintenance.

INCREASED AUXILIARY POWER The JD4 engine offers up to two auxiliary drive pads, providing three times more available auxiliary power. This additional power allows flexibility and enables off-boarding for electrification and hybrid applications.

WORLDWIDE EMISSIONS COMPATIBILITY The JD4 will be compatible with EU Stage IIIA – Stage V emissions levels through common interfaces. The engine is low-NOx-ready with planned external cooled exhaust gas recirculation (EGR) and a single overhead cam shaft valvetrain. The JD4 engine is also compliant with U.S. EPA Final Tier 4 and EU Stage V with no EGR.

CUSTOMER VALUE The JD4 offers a low purchase price and integration cost, with performance benefits that contribute to overall customer value.

COMPACT ENGINE PACKAGE The JD4 features a 20% to 30% reduction in package size and a more than 100 kg (220 lb) reduction in weight compared to the John Deere 4.5L single turbo engine. This compact design gives customers improved visibility and fuel efficiency.

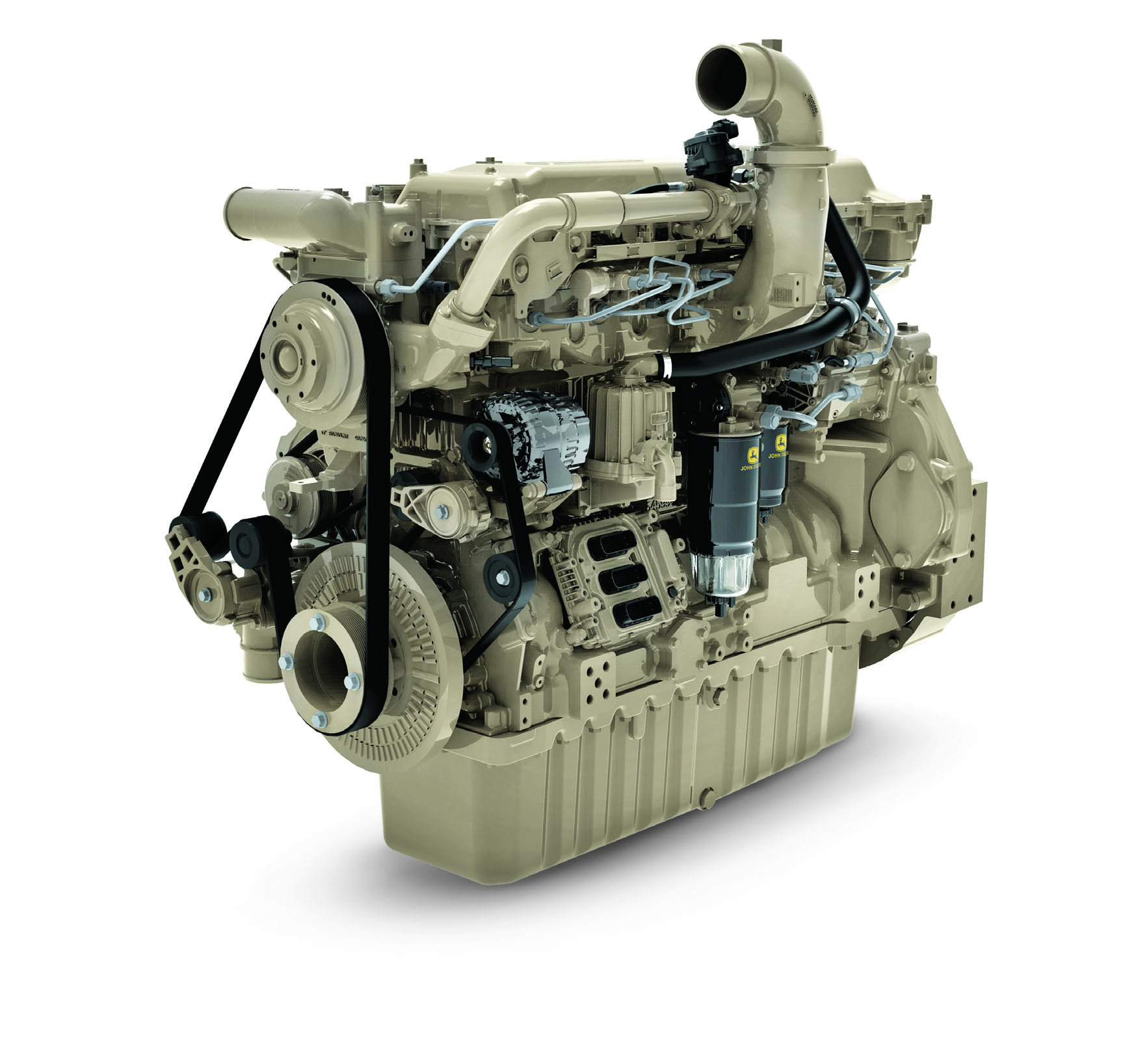

JD9 Engine 205 – 343 kW (275 – 460 hp)

BUILT ON A SOLID FOUNDATION. The new JD9 engine expands on the proven performance of the existing John Deere PSS 9.0L engine, offering uncompromising reliability and power while streamlining complexity and installation costs.

MORE POWER. The JD9 expands our 9.0L lineup by stretching the maximum power output up to 343 kW (460 hp) and peak torque up to 1883 Nm (1389 lb-ft).

VALUE CHOICES. Single- and dual-turbo configurations provide users with versatility to meet specific needs. The new single-turbo option improves integration and packaging for a cost-effective power solution.

ENHANCED RELIABILITY. The engine’s simplified in-line aftertreatment system reduces connection points and streamlines integration. By eliminating and reducing various ATD sensors and parts, the JD9 provides greater reliability. Model-based controls also allow for improved fuel consumption and transient response. The JD9 is compatible with renewable diesel fuel and biodiesel blends.

CONNECTED UPTIME. The JD9 engine comes equipped with John Deere Connected Support™ technology. There are no subscription fees or ongoing expenses. With your approval, this proactive monitoring system allows technicians to remotely diagnose issues to help keep your machines running strong.

SIMPLIFIED AFTERTREATMENT. The JD9 is compliant with U.S. EPA Final Tier 4, CARB, and EU Stage V emissions regulations. It features a durable in-line aftertreatment system with fewer connection points than the previous generation for ease of application integration.

Proven and Ready JD14 Engine JD14 Output : 300 kW (400 hp) - 510 kW (684 hp)

SOLID PERFORMANCE The JD14 engine provides more power per litre than 13.5L configurations. With 14% higher power and 11% increased peak torque, it allows your machines to work faster, lift more, and operate more efficiently than ever before. This engine has been shown to increase harvesting capacity by up to 45% on John Deere X Series Combines. The JD14 features a rear gear train that reduces noise by up to 3 decibels compared to the 13.5L engine. That’s half as loud, greatly improving operator comfort.

EASY TO MAINTAIN. LOW SERVICE COSTS John Deere engineers streamlined common maintenance steps on the JD14 engine. Hydraulic lash adjusters decrease valve wear and provide longer engine life while eliminating valve lash maintenance. An advanced control system analyses sensor data to keep operators working without interruption. Prognostic capabilities are built into the engine to help users identify potential problems and schedule service prior to downtime. Proven John Deere cooling packages are available with JD14 engines for easy, low-cost integration.

FIELD PROVEN John Deere JD14 engines have been working more than 47,000 hours at high load in a variety of applications, including John Deere combines and sugar cane harvesters. Likewise, they’ve demonstrated more than 14,000 hours of torque and lugging power in tractor operations. So, when you install a John Deere JD14 engine in your application, you can be confident in the performance it delivers. Many of these operating challenges were even more extreme than typically confronted in the field: repeating high to low loads to confirm thermal durability, block loading to show strength, and ultra-low idling to demonstrate oil pressure capabilities.

OPERATIONAL FLEXIBILITY The compact JD14 engine is shorter and narrower to fit in more machines with minimal reconfiguration. It provides up to 130 kW (174 hp) through forward auxiliary connections and via an integrated rear SAE-C PTO. It has common connection points across different emissions configurations for the U.S. and Europe and is available in single-and dual-turbo configurations to maximise packaging flexibility. Our durable inline aftertreatment provides unified packaging to reduce connection points and improve reliability. It is available with a DPF for Stage V applications and with no DPF for Final Tier 4 applications.

Expanded Power JD18 Engine JD18 Output : 522 kW (700 hp) - 677 kW (908 hp)

JOHN DEERE POWER RANGE EXTENDED New to the John Deere lineup, the JD18 extends the rated power range to 522 – 677 kW (700 – 908 hp).

UPTIME-FOCUSED CONTROLS Improved John Deere model-based controls offer better diagnostic capabilities, enabling future prognostics and the ability to target the source of engine performance issues.

DESIGNED FOR EXTREME DURABILITY The JD18 features a bedplate design, providing structural benefits for extreme durability. It is built for 20,000 hours of operation with the ability to be rebuilt two times.

SERVICEABILITY AND REPAIRABILITY The JD18 engine was designed with ease of service and repair in mind. Hydraulic lash adjusters offer a maintenance-free valve train, eliminating the need to reset lash.

FLUID MANAGEMENT The JD18 features new combustion technology which allows John Deere to offer an engine in the 522 – 677 kW (700 – 908 hp) power range without aftertreatment. Without the need for DEF, the customer has one less fluid to manage. The high-pressure common-rail (HPCR) fuel system allows the engine to deliver optimised fluid consumption. And the Diamond Like Coating (DLC) improves biodiesel compatibility and system robustness.

RELIABILITY THROUGH INNOVATION The new combustion technology offers a simplified air system, with fixed and wastegate turbo’s, allowing the engine to meet emissions requirements without applying aftertreatment. This feature provides simplified engine integration and a compact package size. AUXILIARY POWER It features a rear gear train for excellent direct power and quiet operation. With options for up to two rear auxiliary drives, the JD18 produces a total of 902 Nm (665 lb-ft) maximum torque.

Engine Registration

To register a John Deere engine, find its serial number on a tag on the engine block or via a QR code on a label near the fuel or oil filter. Then, visit John Deere's warranty registration website here Product Registration. Registering your engine provides access to warranty services, faster service, and information on new products and offers.

If you would like any further information on the John Deere range of products, please contact us

Or alternatively, visit www.deere.co.uk

Find a John Deere dealer near you

For expert advice and support contact your nearest John Deere Industrial dealer.

Download Our Brochure

Featuring more information on the John Deere range.

Service & Support

Barrus is committed to the highest standards of customer service.

Contact Us

Marketing Department,E.P. Barrus Ltd,

Glen Way,

Launton Road

Bicester, Oxfordshire

OX26 4UR

Tel: 01869 363636

Email: customerservices@barrus.co.uk

VAT Number: GB226662558

Company Registration Number: 148476